NOP Filter Pumps

FILTER PUMPS

-

Save Space & Resources

-

Reduce Frequency of Tank Maintenance

-

Reduce Machining Defects

-

Improves Machining Accuracy

-

Media-Free Environmentally Friendly

High Pressure (7 Mpa ~ 70 Bar)

FEATURES OF YTH-EP

An All-in-one, High-to-medium Pressure coolant Unit

All components of a coolant system are consolidated into a single expands the available plant space, resulting in a higher production efficiency.

- Maximum operating pressure: 7.0 MPa.

- No suction filter is required.

- No inline filter is required.

- No plumbing is required to interconnect various components.

Turbulence™ Filter

Turbulence™ Filter

Turbulence™ Filter

Turbulence™ Filter

Our special TurbulenceTM design generates turbulence around the surface of filter with 2 wing-shaped vanes rotating around filter and can wash away sludge from filter surface continuously.

PERFORMANCE CURVES

Water Soluble coolant [General Performance]

Test oil: JIS K2241 A3 solution containing 2% Water soluble cutting fluid.

High Efficiency Plunger Pump

-

Compatible fluid type

- Water soluble coolant (Please consult us if you use non-water soluble coolant).

- Incompatible with lubricant oils, fuel oils.

- Relief valve is built into the pump.

Incompatible with clear water, demineralized water, aqueous solutions and viscous fluids without rust-preventive property, corrosive fluids, solvents and any cutting fluids that contain active sulfur.

Filter Rating (Nominal value)

| Suction strainer | 3mm (Solids larger than this must be removed from the tank.) |

|---|---|

| Filter | 20 µm, 50 µm |

*Please consult us if you use non-water soluble coolant.

SAMPLE SYSTEM LAYOUT

High Pressure (7 MPa ~ 3 MPa)

FEATURES OF YTH-CP

An All-in-one, High-to-medium Pressure coolant Unit

All components of a coolant system are consolidated into a single expands the available plant space, resulting in a higher production efficiency.

- Maximum operating pressure: 7.0 MPa.

- No suction filter is required.

- No inline filter is required.

- No plumbing is required to interconnect various components.

Double Cyclone Filter

Double Cyclone Filter

Double Cyclone Filter

Double Cyclone Filter

Suction coolant from suction impeller enters to single primary cyclone in centre and this pre-filtered coolant then enters into six secondary filters, delivering filtered coolant of 50microns to plunger to develop desired pressure as per application.

High Efficiency Plunger Pump

Piston action pushes fluid at high to medium pressure

PERFORMANCE CURVES

50Hz

PERFORMANCE CURVES

Water Soluble coolant [General Performance]

Test oil: JIS K2241 A3 solution containing 2% Water soluble cutting fluid.

Filter Rating (Nominal value)

| Suction strainer | 3mm (Solids larger than this must be removed from the tank.) |

|---|---|

| Filter | 50 µm |

*Please consult us if you use non-water soluble coolant.

SAMPLE SYSTEM LAYOUT

Medium Pressure (2 Mpa ~ 20 Bar)

FEATURES OF YTH-CS

An All-in-one, medium Pressure coolant Unit

All components of a coolant system are consolidated into a single pump. The saved space expands the avilable plant space, resulting in a higher production efficiency.

- Maximum operating pressure: 2.0 MPa.

- Maximum Flow rate: 28.8 liters/min

- No inline filter is required.

- No plumbing is required to interconnect various components.

Double-Cyclone Filter

Double-Cyclone Filter

Double-Cyclone Filter

Double-Cyclone Filter

A proprietary double cyclone sysytem remove sludge. The first cyclone removes larger debris, while the second cyclones remove smaller particles. The inline filter cleaning cycle is extended by 24 times.

*sludge larger than 20um can be removed.(When using water soluble coolant fluid.)

PERFORMANCE CURVES(YTH-CS)

Water Soluble coolant [General Performance]

Test oil: JIS K2241 A3 solution containing 2% Water soluble cutting fluid.

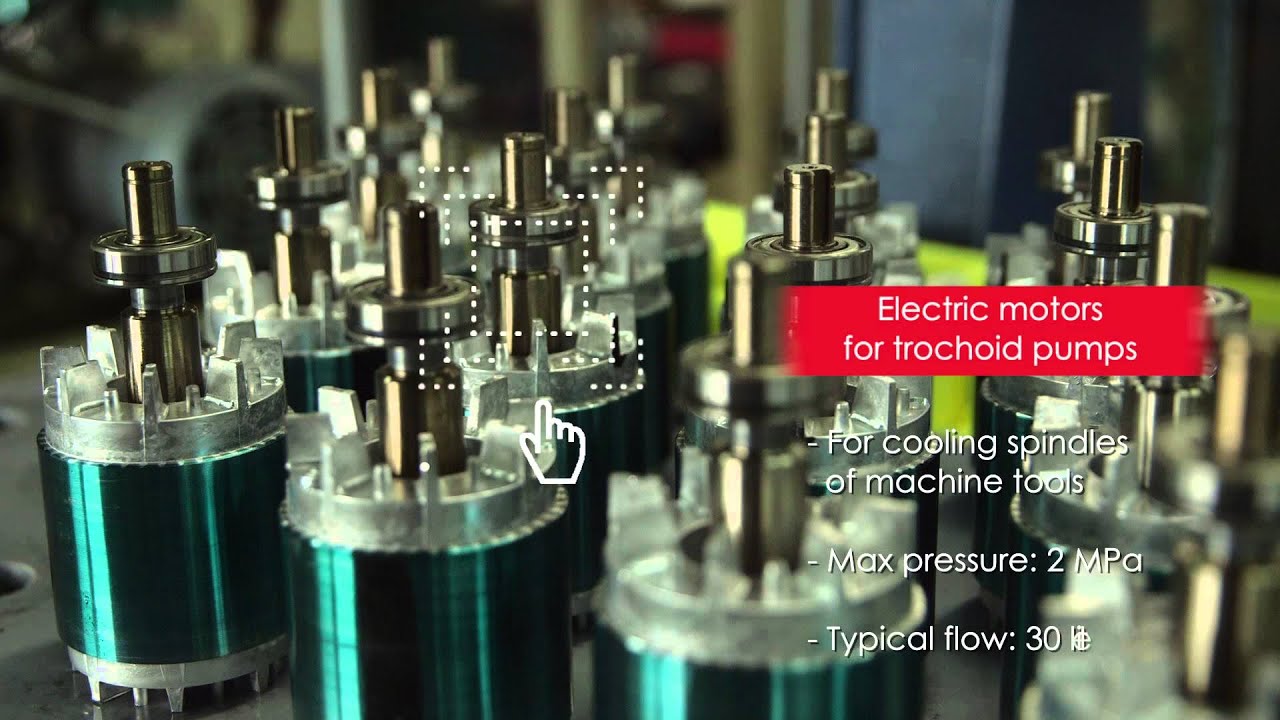

High Efficiency Trochoid Pump

CS employs a Trochoid pump which excels in fluid control efficency. The double-cyclone system sorts out sludge and enables direct connection to the coolant tank

-

Compatible fluid type

- Water soluble coolant.

- Incompatible with non-water soluble coolant, lubricant oils, fuel oils.

- Incompatible with clear water, demineralized water, aqueous solutions and viscous fluids without rust-preventive property, corrosive fluids, solvents , oil-based materials.

- Relief valve is built into the pump.

Filter Rating (Nominal value)

| Suction strainer | 3mm (Solids larger than this must be removed from the tank.) |

|---|---|

| Filter | Water-soluble coolant fluid 50 μm: 95% (Specific weight 2.7) 100 μm: 99.9% (Specific weight 2.7) |

*Be sure to install an unloading valve in the outlet pressure line if running the pump intermittently

SAMPLE SYSTEM LAYOUT

Large Flow Low Pressure coolant Unit

YTH-GCI is designed to deliver large flow at low pressure with built-in cyclone filter. Its compact design enables easy retrofitting to your existing tank of NC lathe, machining center or grinding machine, etc.

The large flow also ensures high efficiency in sludge removal, which substantially reduces problems around the tank, such as dimensional deviation of workpieces, clogged plumbing due to excessive accumulation of sludge.

- Total Pump Head: 35-65 m

-

Maximum Flow Rate

- GCI 07*CG: 70 L/min

- GCI 13*CG: 135 L/min

- GCI 30*CG: 300 L/min

Cyclone Filter

Cyclone Filter

Cyclone Filter

Cyclone Filter

This unique reversed cyclone system can separate clean coolant and dirty coolant inside the pump. Dirty coolant is pushed up through the side surface of cyclone filter by centrifugal force and discharged with sludge. Filtered clean coolant is collected to the center of cyclone filter and boosted up by multiple-stage impellers.

Filter Rating (Nominal value)

| Suction strainer | 3mm (Solids larger than this must be removed from the tank.) |

|---|---|

| Cyclone filter | Water soluble coolant 100 μm: 99.9% (Specific weight 2.7) Straight oil 100 μm: ≧ 80% (Specific weight 2.7) |

Impeller Pump

YTH-GCI employs impellers whose design is best suited for supplying large quantity of coolant and capable of boosting up pressure with its multiple stage impellers

-

Compatible fluid type

- Water soluble cutting fluids

- Non-water soluble coolant with kinematic viscosity of 22 mm2/s or less

- Incompatible with lubricant oils and fuel oils.

- Incompatible with clear water, demineralized water, aqueous solutions and viscous fluids without rust-preventive property, corrosive fluids, solvents, oil-based materials.

NOP Cyclone Filter Pump: Model GCl-75

Big Flow coolant Pump with Built-in Cyclone Filter

- Total Pump Head: 50 m

- Maximum Discharge: 95 LPM

- No Suction Filter

- No Clean Tank

- 1.1 Kw Motor

*Aqueous solution with 2% or more water-soluble coolant fluid

Cyclone Filter

Cyclone Filter removes chips from coolant fluid

Impeller Pump (5 Impeller - 50Hz)

Impeller generates pressure rotating and driving fluid.

Developed for fluid transfer pump.

NOP Cyclone Filter Pump: Model GCl-135

Big Flow coolant Pump with Built-in Cyclone Filter

- Head: 50 m

- Maximum Discharge: 150 LPM

- No Suction Filter

- No Clean Tank

- 1.5 Kw Motor

*Aqueous solution with 2% or more water-soluble coolant fluid

Cyclone Filter

Cyclone Filter removes chips from coolant fluid

Impeller Pump (5 Impeller - 50 Hz)

Impeller generates pressure rotating and driving fluid.

Developed for fluid transfer pump.

NOP Cyclone Filter Pump: Model GCl-303

Big Flow coolant Pump with Built-in Cyclone Filter

- Head: 48 m

- Maximum Discharge: 350 LPM

- No Suction Filter

- No Clean Tank

- 2.2 Kw Motor

*Aqueous solution with 2% or more water-soluble coolant fluid

Cyclone Filter

Cyclone Filter removes chips from coolant fluid

Impeller Pump (3 Impeller - 50 Hz)

Impeller generates pressure rotating and driving fluid.

Developed for fluid transfer pump.

Performance: GCI (50 Hz)